© 2018 CMEC AQUA Valve Manufacturing Co.,LTD. All rights reserved. Site Map Link Designed by iwonder.cn

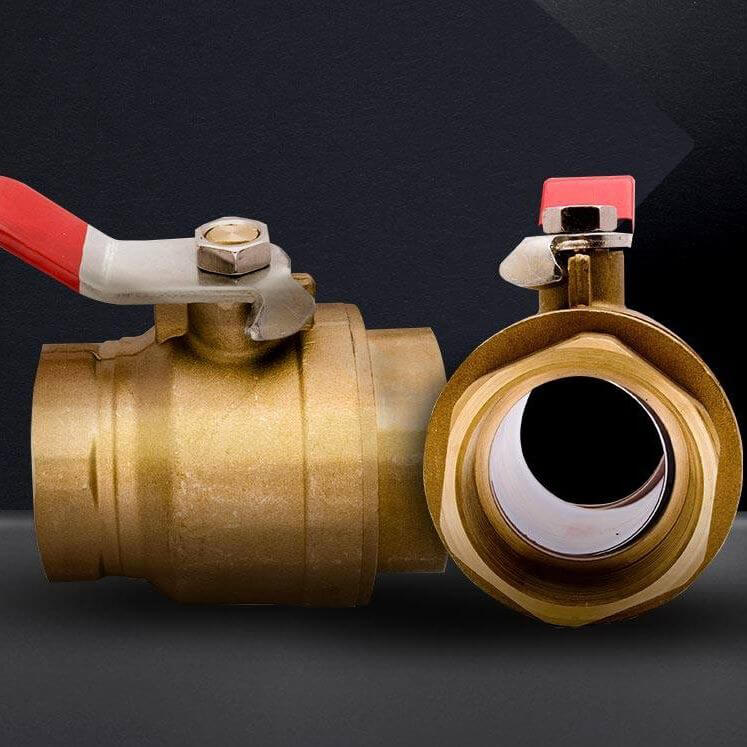

If you are familiar with ball valves, they are installed in a flow control system to facilitate and manipulate the flow of the fluids flown through it. Balls valves manufactures design to endure a series of fluid temperature, fluid flow, and pressure of the fluid for the completion of the project. If you are planning on purchasing ball valves for a project, the following guideline can help you in choosing a ball valve that meets the criteria of your project.

Choosing a ball valve for a project initially requires you to check the working pressure of the fluids, which will be flown through the ball valve. If you are manufacturing certain shut-off applications, you should be aware of the range of the working pressure, which will be facilitated through the ball valve to acquire optimal outcomes.

When choosing a ball valve, you should also determine the temperature range which will be flown through the ball valve. A majority of the shutoff applications are equipped with the ability to manage the flow of fluid at various temperatures. However, you should be considerate of choosing the temperature of the fluid, which will be passed through the valve. By doing so, it will narrow down your hunt for a ball valve.

Also, brass ball valves are tailored using assorted materials, which include stainless steel, ceramic, and PVC, and each of the components used in its manufacturing plays a crucial role at various temperature ranges.

A specified range of flow control systems and applications pertain to different viscosities and buoyance of fluids. In correspondence to that, certain valve systems are designed accordingly to withstand variations of fluid components. Being familiar with a type of fluid assists you in narrowing down your hunt for a brass ball valve, which could be included to a flow system, as a part of the project.

If you are conflicted about choosing a ball valve for your project, you should focus on the fluid volume of the flow to narrow down your pick. As various flow control applications are involved in the management of fluids at different rates, it will require you having resourceful knowledge on the size of the valve before your proceed further with your purchase.

As mentioned earlier, when working on a flow control system project, you will be required to work on four modules, which includes fluid volume, fluid type, temperature, and working pressure of the fluid, and each factor attributes to the general cost of the ball cost. It also includes the cost provided to ball valve manufacturers for preparing a range of ball valves for you. The general costs also comprise the valve size and composition of the valves. Once you have accumulated and jolted down the general costs involved for investing in brass ball valve, you can start working on estimating the installation costs of the ball valve.

When investing in brass ball valves, you are required to take the estimated cost of installation along with the general expenses to narrow down your pick, as investing in an ideal ball valve for a flow control system is also in congruence with its installation expenses. When working on a project, a workforce will be included in the installation of the valve and its materials so, you should also include such installation expenses to your budget prior to choosing a ball valve for your project.